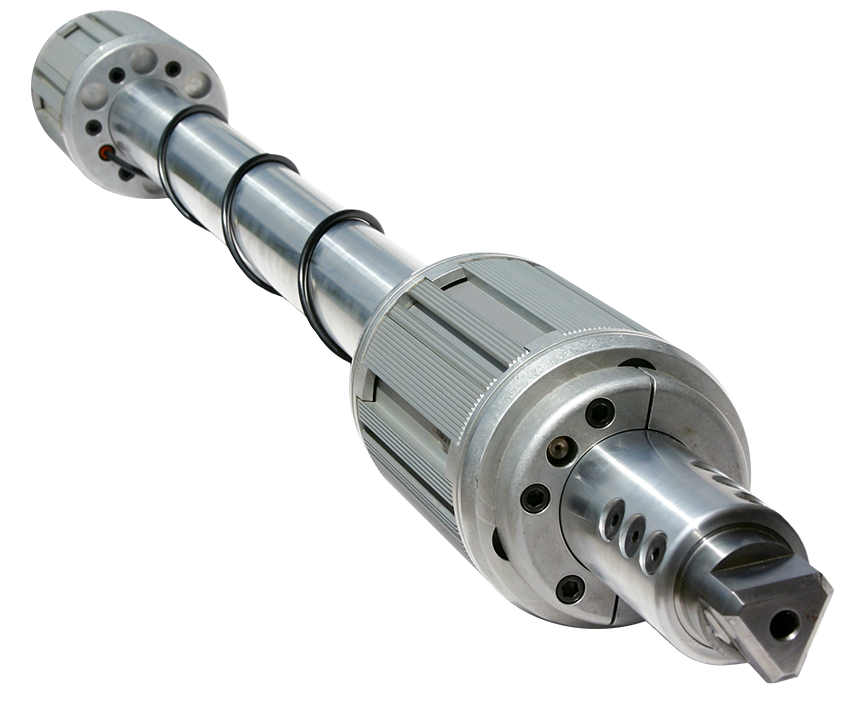

These shafts provide a lightweight alternative to a bulky and heavy shaft that runs larger diameter cores. The Through Shaft can be made with a steel or aluminum body. It can be designed with a diameter from 5” to 16” and face length up to 150”.

A thru shaft is a component used in a variety of mechanical systems, including engines, transmissions, and industrial machinery. It is a long, cylindrical shaft that passes through a housing or a set of bearings to transmit torque or power.

In automotive applications, a thru shaft can be used to transmit power between two components in the engine or transmission. For example, in a manual transmission, the thru shaft is used to connect the input shaft to the output shaft, allowing power to be transmitted from the engine to the wheels.

Thru shafts can be made from a variety of materials, including steel, aluminum, and titanium. They are typically designed to be durable and withstand the high stresses and loads that are common in mechanical systems.

Some of the benefits of a thru shaft include:

- Efficient power transmission: The thru shaft allows for efficient power transmission between two components, minimizing power losses and maximizing the efficiency of the system.

- Compact design: Thru shafts can be designed to be very compact, which can be useful in applications where space is limited.

- Reduced wear and tear: By transmitting power directly between two components, a thru shaft can help to reduce wear and tear on other components that might otherwise be subjected to higher stresses and loads.

- Improved reliability: A thru shaft can improve the reliability of a mechanical system by providing a direct and reliable means of transmitting power.

- Versatile: Thru shafts can be used in a wide range of applications and can be designed to suit a variety of different requirements and specifications.

The Thru Shaft is an important component of many mechanical systems and provides several benefits related to power transmission, reliability, and versatility.